Proton Exchange Membrane for Fuel Cell

Product Description

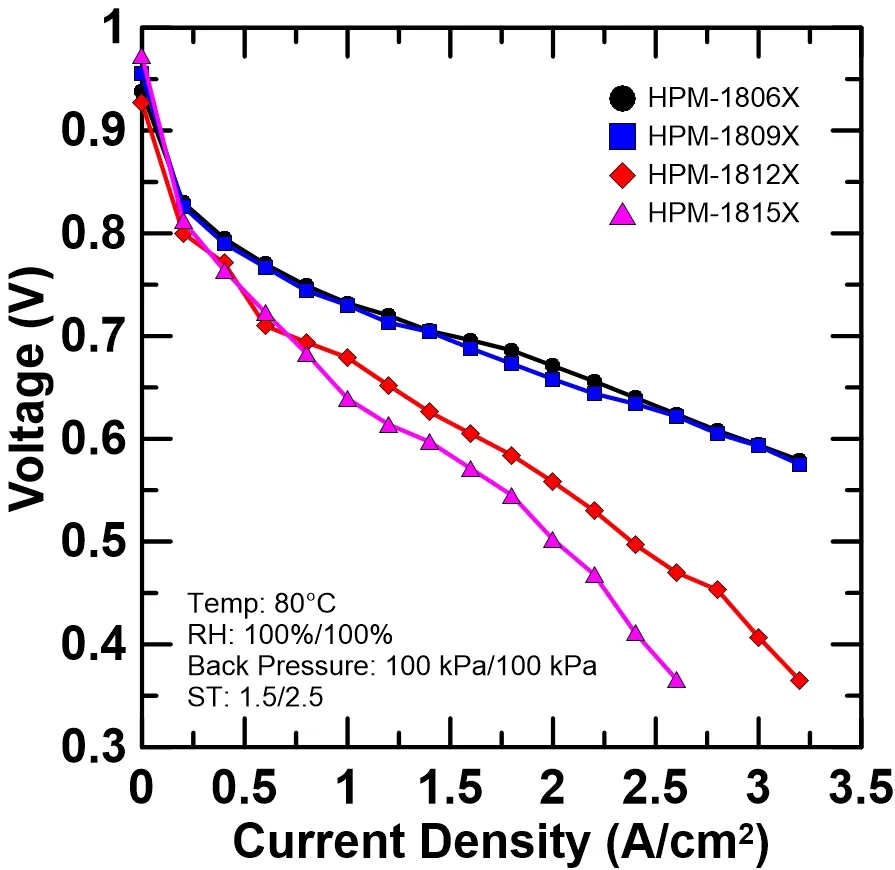

The HPM series proton exchange membrane for fuel cells is a reinforced perfluorosulfonic acid proton exchange membrane (PEM) widely used in fuel cell stacks. It has high proton conductivity, high selectivity, and high stability in both acidic and corrosive environments. Membranes are identified by type and identification (batch) number.

|

Specification |

HPM-1806X |

HPM-1809X |

HPM-1812X |

HPM-1815X |

||||

|

Thickness, μm |

6±0.5 |

9±0.5 |

12±1.0 |

15±1.0 |

||||

|

Density, g/cm3 |

2.05±0.05 |

|||||||

|

Ionic Exchange |

950-1050 |

950-1050 |

950-1050 |

950-1100 |

||||

|

Tensile Strength, MPa |

TD |

MD |

TD |

MD |

TD |

MD |

TD |

MD |

|

≥55 |

≥55 |

≥50 |

≥50 |

≥45 |

≥45 |

≥40 |

≥40 |

|

|

Breaking Elongation, % |

≥80 |

≥100 |

≥100 |

≥100 |

||||

|

Linear Swelling Rate(80℃/1h), % |

≤3 |

|||||||

|

Test Standards |

GB/T 20042.3-2022 |

|||||||

Test Requirements:

1.Before testing, please place the membrane samples in a laboratory environment (23±2℃/73.4±3.6℉, 50±5%RH) for 24h ;

2.It is tested with 10mm rectangular spline, tensile rate: 50mm/min.

Delivery Methods:

Product information: Products are cut as required at (23±2℃/73.4±3.6℉,50±5%RH). The fluctuation of ambient temperature and humidity will cause the size change of the membrane. It is recommended to confirm the membrane size requirements with customer service before shipping.

1.The standard size of sheet product includes:

Width: 0.2m - 0.6m

Length: 0.2 m- 0.6m

2.The standard size of roll product includes:

Standard width of roll product:0.36m and 0.72m

Standard length of roll product: 100m and 200m

3.For non-standard customized size: Roll width for special orders is 0.2m-1.2m, minimum order requirement is 100m2(note: special requirements will add additional cost and lead time).

4.Transportation mode: The product is delivered in form of flat sheet or roll. Before use. Please contact customer service if you have special needs.

Activation Methods

It is recommended to refer to the description of section 6.6 of “GB/T 20042.5-2009 Proton Exchange Membrane Fuel Cell Part 5: Test Methods for Membrane Electrode" for single-cell activation.

The steps are as follows:

1.Install the single cellon the fuel cell test platform;

2.Usethe reactive gas as the activation medium, the activation process isaccording to the following operating conditions:

- Reaction temperature l: 75℃/167℉;

- Relative humidity of reaction gas (RH): 100%;

- Stoichiometric ratio of reaction gas: St H2: 1.2, St Air: 2.5;

- Outlet back pressure: 0.1MPa;

- Current density of operating: i≥500mA/cm2;

- Running time:≥4h.

Note: The activation conditions of the cell can also be carried out according to the customer's standards, or by mutual agreement.

Notes

1.Keep the membranepackage closed/sealed before use;

2.Open the package and handle it in a clean and dust-free areain use,all surfaces in contact with the membrane must be smooth and flat (experimental gloves must be worn during operation);

3.Store the membranein its original packaging and stack horizontally to avoid prolonged exposure to light or high temperatures (> 40℃/104℉)after use.