Water Electrolysis Anion Exchange Membrane

Product Description

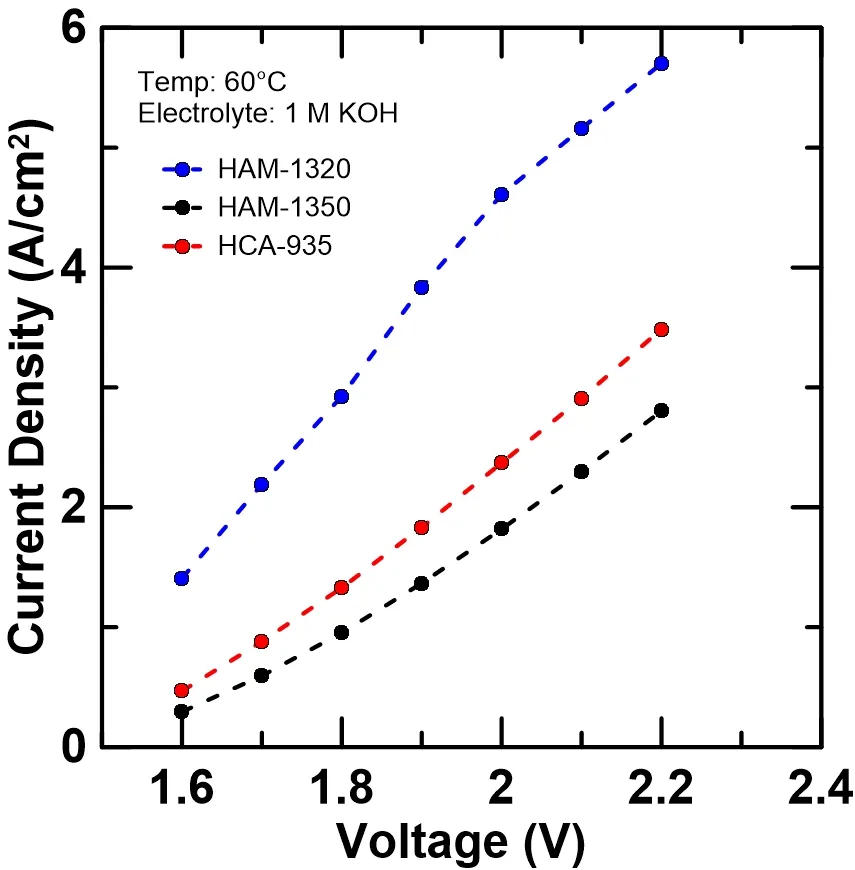

In response to the demand for hydrogen production through electrolysis of water, the independently developed HPA series enhanced anion exchange membrane (AEM) has excellent thermal, chemical, and mechanical stability. Even at low alkaline concentrations, it can achieve high ion conductivity, making the hydrogen production process more stable, economical, and efficient. It is identified by membrane type and identification number (batch number).

|

Specification |

HAM-1320 |

HAM-1350 |

HAM-1380 |

HAM-13100 |

HCA-935 |

|||||

|

Thickness(Dry), μm |

20±1.5 |

50±2.5 |

80±5.0 |

100±5.0 |

35±3.0 |

|||||

|

lon ExchangeCapacity, g/mol |

435-556 |

526-625 |

556-770 |

625-770 |

556-626 |

|||||

|

Water Uptake,% |

≥10 |

≥15 |

≥20 |

≥20 |

≥20 |

|||||

|

Tensile Strength, MPa |

TD |

MD |

TD |

MD |

TD |

MD |

TD |

MD |

TD |

MD |

|

≥40 |

≥40 |

≥30 |

≥30 |

≥20 |

≥20 |

≥15 |

≥15 |

≥50 |

≥52 |

|

|

Elongation at Break, % |

≥90 |

≥90 |

≥90 |

≥90 |

≥44 |

|||||

|

Linear Swelling Ratio, % |

≤2 |

≤5 |

≤5 |

≤5 |

≤3 |

|||||

Test Requirements

1.Polymer IEC in the hydroxide (OH-) counter-ion form.

2.Measured in DI water.

3.Measured from dried to equilibrated in DI water at 25 °C.

Tested with 10mm rectangular sample, tensile rate: 50mm/min.

Pre-treatment Methods

1.For optimal results, please remove the membrane from the backing film before using and immerse it in a large amount of excess 0.5M KOH aqueous solution. These exchanges can be carried out at ambient temperature or 80 ℃,the exchange effect will be better at 80℃ .

2.Please try to minimize the exposure time of the hydroxide form anion exchange membrane in the air, as CO2 in the air can affect the initial performance of the membrane.

3.After exchanging to hydroxide form anion exchange membrane, in order to avoid changes in membrane size, please do not immerse the membrane in deionized water.

4.If it is necessary to clean the membrane, please use KHCO3 solution of similar concentration as the washing solution.

Notes

1.Please store, handle, and process the membrane in a clean and dust-free environment.

2.When cutting the membrane, please use a new sharp knife or blade. When handling the membrane, please be sure to wear protective gloves and do not puncture, wrinkle, or scratch the membrane. Please keep all surfaces in contact with the membrane smooth and clean during handling, inspection, storage, pretreatment, and installation.

3.When stored for a long time, dry membrane should be stored in a sealed state, and wet membrane should be stored in a 3 wt% KHCO3 solution to avoid microbial contamination.

Delivery Methods

Product information: The membrane is delivered in the form of chloride dry film. Products are cut as required at (23±2℃/73.4±3.6℉,50±5%RH). The fluctuation of ambient temperature and humidity will cause the size change of the membrane. It is recommended to confirm the membrane size requirements with customer service before shipping.

1.The standard size of sheet product includes:

Width: 0.2m - 0.6m

Length: 0.2 m- 0.6m

2.The standard size of roll product includes:

Standard width of roll product:0.31m and 0.62m

Standard length of roll product: 50m - 100m

3.For non-standard customized size:

Roll width for special orders is 0.2m-1.2m, minimum order requirement is 100m2(note: special requirements will add additional cost and lead time).

4.Transportation mode:

The product is delivered in form of flat sheet or roll. Before use. Please contact customer service if you have special needs.